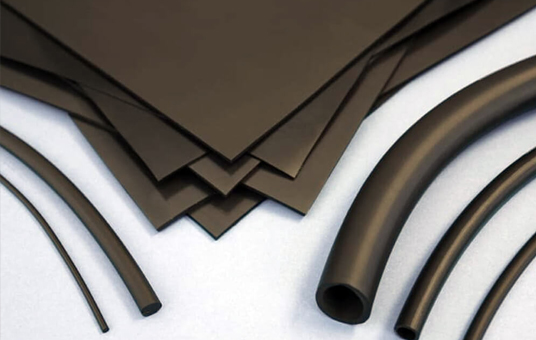

Viton Rubber (FKM)

Excellent resistance to high temperatures, chemicals and oils for extreme applications

View SpecificationsViton Rubber (Fluoroelastomer FKM)

Viton Rubber (FKM - Fluoroelastomer) is a high-performance elastomer recognized for its exceptional resistance to extreme temperatures, aggressive chemicals, oils and fuels.

With an operating temperature range in oil from -20°C to 250°C and excellent chemical resistance, Viton is the ideal material for applications where other elastomers would fail under severe conditions.

High-Performance Properties

Viton Rubber stands out for its unique properties for extreme applications:

- Exceptional resistance to high temperatures up to 250°C in oil

- Excellent chemical resistance to acids, alkalis and aggressive products

- Superior resistance to oils, fats and hydrocarbons

- Excellent ozone and weathering resistance

- Low compression set (15% maximum)

- Excellent aging resistance

These properties make it indispensable in aerospace, automotive, chemical, petroleum industries, and any application requiring maximum reliability under severe conditions.

Technical Data Sheet - Viton Rubber (FKM)

| PARAMETERS | METHOD | SPECIFICATIONS |

|---|---|---|

| SHORE A HARDNESS, Points | ASTM-D2240 | 70 - 75 |

| TENSILE STRENGTH, psi | ASTM-D412 | 1050 MINIMUM |

| ELONGATION, % | ASTM-D412 | 225 MINIMUM |

| TEAR, Lb/Inch | ASTM-D624 | 40 MINIMUM |

| PARAMETERS | METHOD | SPECIFICATIONS |

|---|---|---|

| OZONE RESISTANCE, @40°C, 100 ppm, 72 hours | ASTM-D1171 | CRACK-FREE |

| % COMPRESSION SET, @ 100°C, 22 hours | ASTM-D395 | 15 MAXIMUM |

| % CHANGE IN TENSION @ 100°C, 70 hours | ASTM-D471 | 10 MAXIMUM |

| % CHANGE IN ELONGATION @ 100°C, 70 hours | ASTM-D471 | 15 MAXIMUM |

| % CHANGE IN VOLUME 100°C, 70 hours | ASTM-D471 | 7 MAXIMUM |

| OPERATING TEMPERATURE IN ASTM 1 OIL, °C | ASTM-D471 | FROM -20 TO 250 °C |

| SUBSTANCES | METHOD | SPECIFICATIONS |

|---|---|---|

| FATS, OILS, HYDROCARBONS | ASTM-D471 | EXCELLENT |

| OZONE, LIGHT, WEATHERING | ASTM-D1171 | EXCELLENT |

| CONCENTRATED ACIDS AND ALKALIS | ASTM-D471 | EXCELLENT |

| KETONES AND OTHER OXYGENATED | ASTM-D2137 | NOT RECOMMENDED |

Main Applications

Industries and applications where Viton is the required choice

Petroleum Industry

Seals for drilling equipment, refinery gaskets, and components in contact with crude oil and derivatives.

Automotive

Engine seals, injector gaskets, fuel system gaskets, and under-hood components.

Chemical

Reactor gaskets, chemical pump seals, and components in contact with aggressive products.

Aerospace

Aviation system components, jet engine seals, and high-temperature applications.

Pharmaceutical

Sterilization equipment seals, reactor gaskets, and components requiring high purity.

High Temperature

Oven applications, exhaust systems, turbines, and any environment with extreme temperatures.

Advantages of Viton Rubber

Extreme Temperature Resistance

Operates from -20°C to 250°C in oil, maintaining properties under severe conditions.

Excellent Chemical Resistance

Exceptional performance with acids, concentrated alkalis, and aggressive chemical products.

Superior Oil Resistance

Excellent performance with fats, oils, hydrocarbons, and fuels.

Ozone Resistance

Crack-free after ozone exposure, demonstrating excellent durability.

Low Compression Set

Only 15% maximum compression set, ideal for critical sealing applications.

Long Service Life

Excellent aging resistance and long-term property maintenance.

Viton vs Other Materials

Performance comparison in extreme conditions

Viton (FKM)

Ideal for: Extreme and chemical applications

Silicone

Ideal for: High temperatures and electrical applications

NBR

Ideal for: General applications with oils

Important Considerations

Viton Limitations

Viton is NOT recommended for applications with ketones and other oxygenated solvents. Consult with our technical team to determine compatibility with your specific application.

Recommended Applications

- Fuel and oil systems

- Aggressive chemical environments

- Continuous high temperatures

- Aerospace applications

- Petroleum and chemical industry

Not Recommended Applications

- Ketones (acetone, MEK)

- Esters and ethers

- Ammonia and amines

- Some hydrofluorocarbons

- Oxygenated solvents

Need Viton Rubber for Your Critical Application?

We offer high-quality Viton and specialized technical support for applications in extreme temperature and chemical conditions.