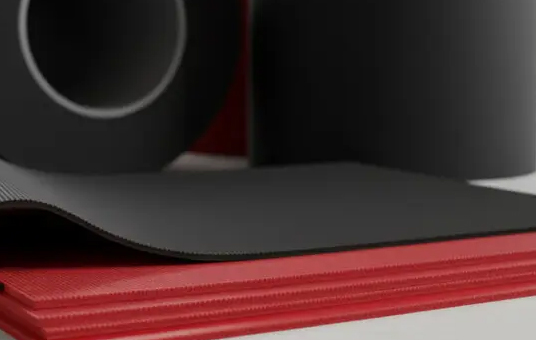

Textile Finish Commercial Neoprene

Fabric-reinforced for enhanced mechanical strength and durability

View SpecificationsTextile Finish Commercial Neoprene

Textile Finish Commercial Neoprene is a high-strength material characterized by its internal fabric reinforcement, which provides greater dimensional stability and mechanical resistance against loads and tensions.

This material combines the excellent properties of neoprene with the additional strength of textile reinforcement, making it ideal for structural, support, and applications requiring maximum durability under demanding working conditions.

Advantages of Fabric Reinforcement

The fabric reinforcement incorporated into the neoprene provides significant benefits:

- Higher tensile strength and mechanical load capacity

- Superior dimensional stability under tension

- Reduced elongation under continuous load

- Better performance in structural applications

- Extended durability under severe working conditions

Ideal for applications where the material needs to maintain its shape and properties under constant or variable loads.

Technical Data Sheet - Textile Finish Commercial Neoprene

| Parameter | Method | Specifications |

|---|---|---|

| Hardness Shore A | ASTM-D2240 | 60 - 65 |

| Tensile Strength (psi) | ASTM-D412 | 350 psi minimum |

| Elongation % | ASTM-D412 | 375 minimum |

| Tear Strength (KN/m) | ASTM-D624 | 16 minimum |

| Temperature Range (°C) | ASTM-D573 | -20°C to 90°C |

| Sound Insulation Factor | - | High |

| Vibration Absorption | - | Excellent |

| Impact Absorption | - | High |

| Substance | Method | Specifications |

|---|---|---|

| Chemical Resistance | ASTM-D471 | Good |

| Acid & Alkali Resistance | ASTM-D471 | Good |

| Alcohol Resistance | ASTM-D471 | Very Good |

| Sheet | Roll | Roll |

|---|---|---|

| 1m x 1m, thickness from 1/16" to 3" | 1m x 10m, thickness from 1/16" to 5/16" | 1m wide x 5m long, thickness from 3/8" to 5/8" |

Main Applications

Industrial sectors where fabric reinforcement makes the difference

Structural Supports

Base for heavy equipment, machinery, and structures requiring reinforced cushioning.

High Load Cushioning

Applications requiring support of heavy loads with minimal deformation.

Expansion Joints

Sealing in structures subject to movement, vibration, or thermal expansion.

Advantages of Fabric-Reinforced Neoprene

Integrated Fabric Reinforcement

Built-in fabric providing greater mechanical strength and stability.

Dimensional Stability

Minimal elongation under load, maintains shape in structural applications.

Heavy Load Resistance

Ideal for supporting heavy equipment and industrial machinery.

Oil Resistance

Excellent performance against industrial oils and greases.

Weather Stability

Resistant to ozone, UV, and adverse weather conditions.

Superior Cushioning

Excellent absorption of vibrations and impacts in industrial applications.

Textile Finish or Smooth Neoprene?

Choose the right material for your application

Textile Finish Neoprene

- Ideal for: Structural and support applications

- Main advantage: Higher mechanical strength

- Recommended for: Heavy loads, industrial equipment

- Characteristic: Internal fabric reinforcement

Smooth Neoprene

- Ideal for: Precision sealing and aesthetic applications

- Main advantage: Perfectly smooth surface

- Recommended for: Gaskets, sealing joints

- Characteristic: Uniform mirror finish

Need Fabric-Reinforced Neoprene?

Contact us for technical advice to determine if textile finish neoprene is the best solution for your specific application.