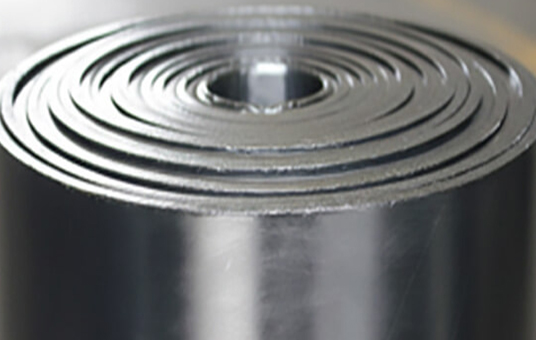

Nitrile Rubber (NBR)

Excellent resistance to oils, fuels, and solvents for industrial applications

View SpecificationsIndustrial Use Nitrile Rubber

Nitrile Rubber (NBR - Nitrile Butadiene Rubber) is a synthetic elastomer renowned for its exceptional resistance to oils, fuels, greases, and solvents. It is the preferred material for applications in contact with hydrocarbons and industrial fluids.

With a Shore A hardness of 65-70, nitrile offers a perfect balance between chemical resistance and mechanical properties, maintaining good flexibility and durability under demanding working conditions.

Superior Chemical Resistance

Nitrile Rubber stands out for its unmatched resistance to:

- Mineral and synthetic oils of all types

- Fuels such as gasoline, diesel, and kerosene

- Industrial greases and lubricants

- Aliphatic solvents and many aromatic ones

- Hydraulic and transmission fluids

This chemical resistance makes it indispensable in automotive, aerospace, petrochemical, and manufacturing industries.

Technical Data Sheet - Industrial Use Nitrile Rubber

| Parameter | Method | Specifications |

|---|---|---|

| Hardness Shore A | ASTM-D2240 | 65 - 70 |

| Tensile Strength (psi) | ASTM-D412 | 375 psi minimum |

| Tear Strength (KN/m) | ASTM-D624 | 15.5 minimum |

| % Elongation Change at 100°C, 72 hours | ASTM-D573 | 375 minimum |

| Operating Temperature (°C) | ASTM-D573 | -16°C to 80°C |

| % Compression SET, @ 100°C, 22 hours | ASTM-D395 | 45 maximum |

| Weather Resistance | - | Good |

| Abrasion | - | Regular |

| Substance | Method | Specifications |

|---|---|---|

| Ozone Resistance, @40°C, 100 ppm, 72 hours | ASTM-D1117 | Minimum cracks |

| Chemical Resistance | ASTM-D471 | Good |

| Grease and Oil Resistance | ASTM-D471 | Good |

| Acid Resistance | ASTM-D471 | Good |

| Sheet | Roll | Roll |

|---|---|---|

| 1m x 1m, thickness from 1/16" to 3" | 1m x 10m, thickness from 1/16" to 5/16" | 1m wide x 5m long, thickness from 3/8" to 5/8" |

Main Applications

Industries where Nitrile Rubber is indispensable

Automotive Industry

Fuel hoses, engine gaskets, seals, and gaskets in contact with oils and fuels.

Industrial Machinery

Gaskets for hydraulic pumps, lubrication systems, and equipment in contact with oils.

Petroleum Sector

Drilling equipment, refineries, and hydrocarbon transportation systems.

Advantages of Nitrile Rubber

Fuel Resistance

Excellent performance with gasoline, diesel, and other fuels.

Oil Resistance

Maintains properties in contact with mineral and synthetic oils.

Chemical Resistance

Good performance with acids, alkalis, and many chemical solvents.

Good Mechanical Properties

Adequate tensile and tear strength for industrial applications.

Temperature Range

Operates efficiently from -16°C to 80°C.

Ozone Resistance

Good behavior against environmental ozone exposure.

When to Choose Nitrile Rubber?

Comparison with other elastomeric materials

Nitrile (NBR)

Ideal for: Applications with oils and fuels

Neoprene

Ideal for: General applications and ozone resistance

SBR

Ideal for: General applications without oils

Need Nitrile Rubber for Your Application?

Contact us for technical advice to determine if nitrile is the ideal material for your specific project.