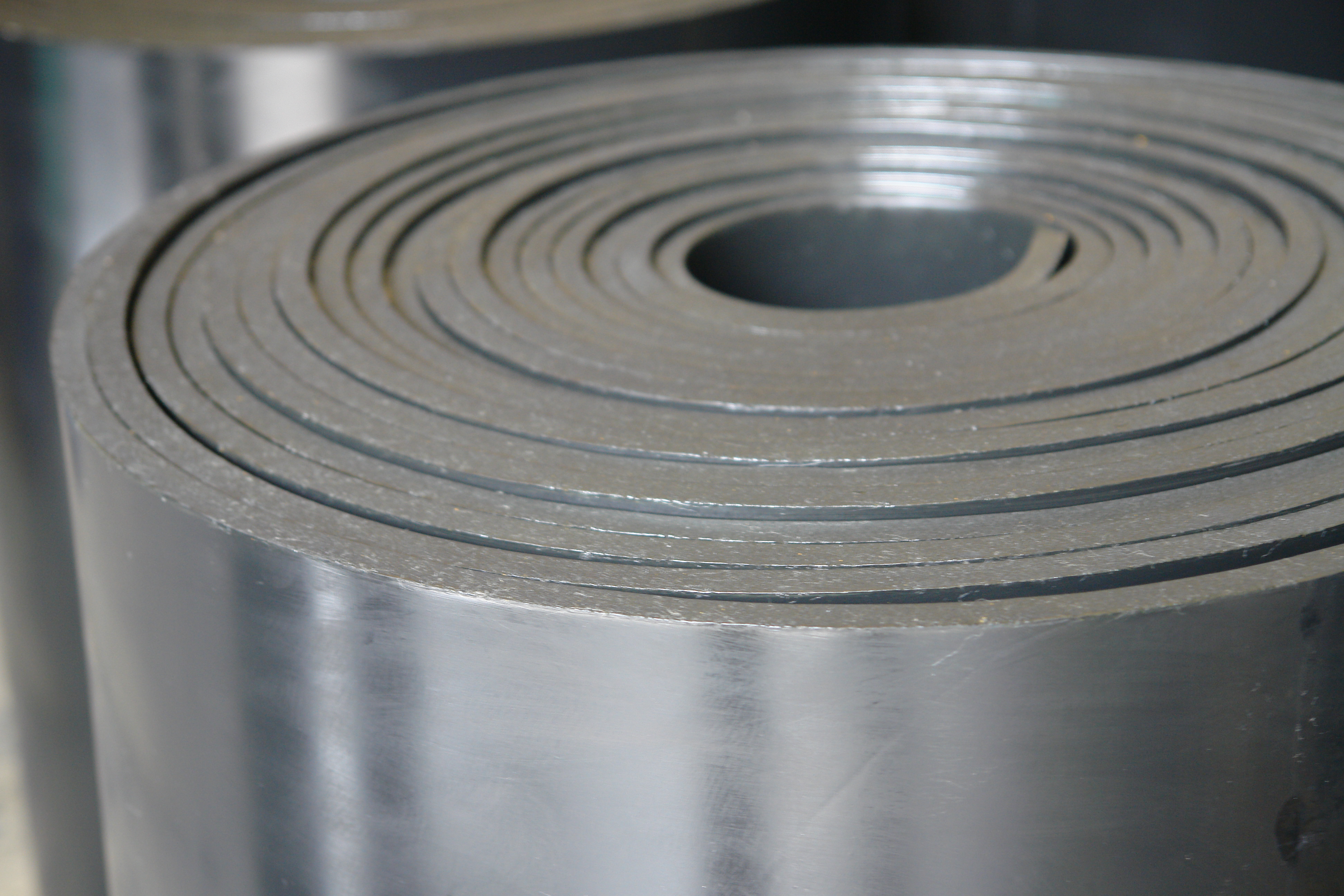

High-Abrasion Apron Rubber

High-Abrasion Apron Rubber provides excellent wear resistance in applications with abrasive materials or high impact. Its formulation ensures high durability against continuous friction, ideal for protecting industrial equipment and structures.

Manufactured with superior-performance elastomers, this armorite apron rubber maintains its mechanical integrity under severe load or pressure conditions. It is ideal for side aprons in conveyor belts and linings in hoppers or ducts.

With a dense structure and good energy absorption, high-abrasion rubber reduces component wear and extends equipment lifespan. It is a reliable option for mining, cement, and aggregate plants seeking to minimize maintenance downtime.

Technical Specifications - High-Abrasion Apron Rubber

| Parameters | Method | Specifications |

|---|---|---|

| Shore A Hardness | ASTM-D2240 | 60 - 65 |

| Tensile Strength (psi) | ASTM-D412 | 350 psi minimum |

| Elongation % | ASTM-D412 | 375 minimum |

| Tear Resistance (KN/m) | ASTM-D624 | 16 minimum |

| Temperature Range (°C) | ASTM-D573 | -20°C to 90°C |

| Acoustic Insulation Factor | - | High |

| Vibration Absorption | - | Excellent |

| Impact Absorption | - | High |

| Substances | Method | Specifications |

|---|---|---|

| Chemical Product Resistance | ASTM-D471 | Good |

| Acid and Alkali Resistance | ASTM-D471 | Good |

| Alcohol Resistance | ASTM-D471 | Very Good |

| Roll |

|---|

|

Rolls of 1/4" to 1" thickness X 15.24 m length (50') in the following widths: 2", 3", 4", 6", 8", 10", 12", 20", 24", 28", 40" and 48" |