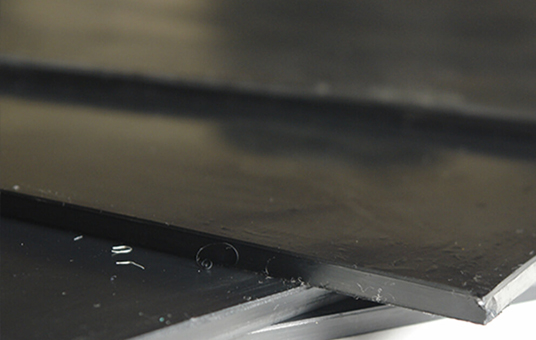

Hydrogenated Nitrile Rubber (HNBR)

Excellent high temperature, oil and chemical resistance for demanding industrial applications

View SpecificationsHydrogenated Nitrile Rubber HNBR

Hydrogenated Nitrile Rubber (HNBR - Hydrogenated Nitrile Butadiene Rubber) is a high-performance elastomer obtained through hydrogenation of conventional nitrile, giving it superior heat, ozone, and chemical resistance properties.

With a Shore A hardness of 70-75 points and an extended temperature range from -39°C to 130°C, HNBR is ideal for applications requiring high mechanical performance and resistance to extreme conditions.

High-Performance Properties

Hydrogenated Nitrile Rubber offers significant advantages over conventional nitrile:

- Superior high temperature resistance up to 130°C

- Excellent resistance to oils, fats, and hydrocarbons

- High mechanical strength (2000 psi minimum)

- Excellent ozone and weather resistance

- Good performance with concentrated acids and alkalis

- Low compression set (20% maximum)

These properties make it ideal for automotive, industrial applications, and severe service conditions where other elastomers would fail.

Technical Specifications - Hydrogenated Nitrile Rubber HNBR

| PARAMETERS | TEST METHOD | SPECIFICATIONS |

|---|---|---|

| SHORE A HARDNESS, Points | ASTM-D2240 | 70 - 75 |

| TENSILE STRENGTH, psi | ASTM-D412 | 2000 MINIMUM |

| ELONGATION, % | ASTM-D412 | 225 MINIMUM |

| TEAR RESISTANCE, Lb/In | ASTM-D624 | 50 MINIMUM |

| PARAMETERS | TEST METHOD | SPECIFICATIONS |

|---|---|---|

| % COMPRESSION SET, @100°C, 24 hours | ASTM-D395 | 20 MAXIMUM |

| % CHANGE IN TENSION @100°C, 70 hours | ASTM-D471 | 15 MAXIMUM |

| % CHANGE IN ELONGATION @100°C, 70 hours | ASTM-D471 | 17 MAXIMUM |

| % VOLUME CHANGE 100°C, 70 hours | ASTM-D471 | 5 MAXIMUM |

| OPERATING TEMPERATURE | ASTM-D471 | FROM -39 TO 130 °C |

| SUBSTANCES | TEST METHOD | SPECIFICATIONS |

|---|---|---|

| FATS, OILS, HYDROCARBONS | ASTM-D471 | EXCELLENT |

| OZONE, LIGHT, WEATHERING | ASTM-D1171 | VERY GOOD |

| CONCENTRATED ACIDS AND ALKALIS | ASTM-D471 | GOOD |

Main Applications

Industries and applications where HNBR is the preferred choice

Automotive

Engine seals, gaskets, oil hoses, and under-hood components exposed to high temperatures.

Heavy Machinery

Hydraulic seals, gaskets for construction and mining equipment in severe conditions.

Oil & Gas

Drilling equipment, seals for downhole tools, and offshore applications.

Hydrogenated Nitrile Rubber Advantages

High Thermal Resistance

Operates continuously from -39°C to 130°C, surpassing conventional nitrile.

Excellent Oil Resistance

Maintains properties when in contact with fats, oils, and hydrocarbons at high temperatures.

High Mechanical Strength

2000 psi tensile strength and 50 Lb/In tear resistance.

Ozone Resistance

Excellent performance against ozone, UV light, and weathering.

Low Compression Set

Only 20% maximum compression set, ideal for sealing applications.

Chemical Resistance

Good performance with concentrated acids and alkalis in various concentrations.

HNBR vs Other Materials

Performance comparison in demanding conditions

HNBR

Ideal for: High temperature applications and severe conditions

Conventional NBR

Ideal for: General applications with oils

FKM (Viton®)

Ideal for: Extreme temperature and chemical applications

Need Hydrogenated Nitrile Rubber for Your Application?

We provide high-quality HNBR and technical advice for demanding applications in high temperatures and severe conditions.