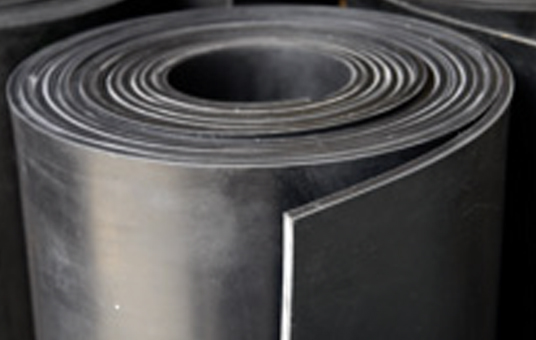

Dielectric EPDM Rubber

Excellent dielectric properties (10 kV/mm minimum) and superior resistance to weather, ozone, and extreme environmental conditions for electrical and outdoor applications.

View Technical SpecificationsDielectric EPDM Rubber for Electrical & Outdoor Applications

Dielectric EPDM (Ethylene Propylene Diene Monomer) is a synthetic elastomer recognized for its exceptional dielectric properties and superior resistance to weather, ozone, and severe environmental conditions.

With a minimum dielectric strength of 10 kV/mm and a wide operating temperature range from -20°C to 145°C, this material is ideal for electrical applications, outdoor sealing, and components exposed to extreme weather conditions.

Dielectric & Environmental Resistance Properties

Dielectric EPDM stands out for its unique properties in electrical and outdoor applications:

- Excellent dielectric properties (10 kV/mm minimum)

- Superior ozone and weather resistance

- Wide temperature range (-20°C to 145°C)

- High elongation (525% minimum)

- Excellent vibration and impact absorption

- Resistance to chemicals and alkalis

These properties make it indispensable in electrical, automotive, construction applications, and any environment requiring resistance to severe environmental conditions.

Technical Data Sheet - Dielectric EPDM

| PARAMETERS | METHOD | SPECIFICATIONS |

|---|---|---|

| HARDNESS, SHORE A | ASTM-D2240 | 60 - 65 |

| TENSILE STRENGTH, psi | ASTM-D412 | 1050 MINIMUM |

| % ELONGATION | ASTM-D412 | 525 MINIMUM |

| TEAR RESISTANCE, KN/m | ASTM-D624 | 20 MINIMUM |

| TEMPERATURE RANGE (CELSIUS) | ASTM-D573 | -20°C TO 145°C |

| WEATHER RESISTANCE | - | EXCELLENT |

| SOUND INSULATION FACTOR | - | VERY GOOD |

| VIBRATION ABSORPTION | - | VERY GOOD |

| IMPACT ABSORPTION | - | VERY GOOD |

| MINIMUM DIELECTRIC STRENGTH | - | 10 kV/mm |

| SUBSTANCES | METHOD | SPECIFICATIONS |

|---|---|---|

| OZONE RESISTANCE, @40°C, 200 PPHM, 72 HOURS | ASTM-D1149 | NO CRACKS |

| CHEMICAL RESISTANCE | ASTM-D471 | GOOD |

| ACID AND ALKALI RESISTANCE | ASTM-D471 | GOOD |

| ALCOHOL RESISTANCE | ASTM-D471 | EXCELLENT |

Main Applications

Industries and applications where Dielectric EPDM is the ideal choice

Electrical Industry

Insulators, transformer seals, substation components, and electrical distribution equipment.

Automotive

Window seals, door gaskets, air conditioning system components, and exterior parts.

Construction

Window and door gaskets, perimeter seals, roofing membranes, and waterproofing systems.

Advantages of Dielectric EPDM

Excellent Dielectric Properties

Dielectric strength of 10 kV/mm minimum, ideal for electrical and insulation applications.

Superior Weather Resistance

Excellent performance against ozone, UV light, rain, and extreme weather conditions.

Wide Temperature Range

Operates from -20°C to 145°C, maintaining its properties under extreme conditions.

High Elongation

525% minimum elongation, providing excellent flexibility and deformation capacity.

Vibration Absorption

Excellent vibration damping and impact absorption for dynamic applications.

Chemical Resistance

Good performance with chemicals, acids, alkalis, and excellent with alcohols.

EPDM vs Other Materials

Performance comparison in outdoor and electrical applications

EPDM

Ideal for: Outdoor and electrical applications

Silicone

Ideal for: High temperatures and medical applications

Neoprene

Ideal for: General applications and medium oil resistance

Need Dielectric EPDM for Your Project?

We provide high-quality Dielectric EPDM and technical support for electrical, construction, and outdoor applications.