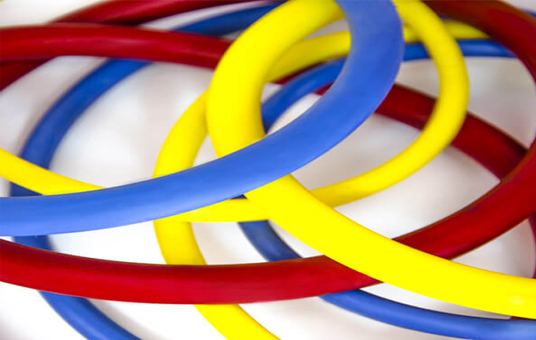

Fluorosilicone O-Rings

Excellent resistance to fuels, oils, and extreme temperatures for critical applications

View ApplicationsFluorosilicone O-Rings

Fluorosilicone O-Rings are high-performance elastomeric seals that combine the excellent temperature properties of silicone with the superior chemical resistance of fluorocarbons.

Specially designed for applications requiring resistance to fuels, oils, solvents, and extreme temperatures, these O-Rings offer reliable performance in the most demanding environments.

Key Technical Properties

Fluorosilicone O-Rings offer unique advantages for critical applications:

- Excellent resistance to fuels and oils including jet fuel, diesel, and synthetic oils

- Wide temperature range from -60°C to 200°C

- Superior resistance to solvents and chemical products

- Good compression set properties for effective sealing

- Resistance to weathering and ozone

- Does not support fungal growth or biological degradation

- Available in standard colors for easy identification

These O-Rings are the ideal choice for aerospace, automotive, and chemical process applications where performance in extreme conditions is critical.

Technical Properties of Fluorosilicone

Performance specifications and characteristics

Temperature Range

Continuous operation: -60°C to 200°C

Maximum peak: Up to 230°C for short periods

Thermal stability: Excellent property retention

Chemical Resistance

Excellent: Fuels, oils, oxygenated solvents

Good: Hydraulic oils, water, saline solutions

Limited: Ketones, esters, aromatic hydrocarbons

Mechanical Properties

Hardness: 50 to 80 Shore A

Tensile strength: 500 - 900 psi

Elongation: 150% - 400%

Compression set: 10% - 25%

Environmental Resistance

Ozone: Excellent resistance

UV and weathering: Very good

Humidity: Excellent

Fungi/mold: Does not support growth

Fluorosilicone vs Other Materials

Performance comparison in critical applications

Fluorosilicone (FVMQ)

Ideal for: Aerospace, automotive, chemical

Silicone (VMQ)

Ideal for: Food, medical, high temperature

Viton (FKM)

Ideal for: Aggressive chemicals, very high temperature

Main Applications

Industries where Fluorosilicone is the preferred choice

Aerospace

Fuel systems, engines, hydraulic systems, and aircraft components.

Automotive

Fuel injection systems, transmissions, emission systems, and under-hood components.

Chemical Processes

Process equipment, pumps, valves, and systems handling solvents and chemicals.

Oil and Gas

Drilling equipment, refineries, and systems handling fuels and oils.

Electronics

Component sealing in environments with cleaning solvents and severe conditions.

Military and Defense

Critical applications in weapon systems, military vehicles, and field equipment.

Advantages of Fluorosilicone

Superior Fuel Resistance

Excellent performance with jet fuel, diesel, gasoline, and other fuels, maintaining integrity and sealing properties.

Wide Temperature Range

Operates from -60°C to 200°C, covering cryogenic and high-temperature applications.

Excellent Environmental Resistance

Resistant to ozone, weathering, humidity, and does not support fungal or mold growth.

Chemical Compatibility

Excellent resistance to solvents, oils, many chemical products, and hydraulic fluids.

Good Mechanical Properties

Optimal balance between flexibility, strength, and low compression set for effective sealing.

Color Availability

Available in various colors for easy identification and coding in complex applications.

Standards and Specifications

Compliance with international standards

AMS 7276

O-Rings, Fluorosilicone Rubber -65° to 400°F

AMS 7277

O-Rings, Fluorosilicone Rubber -65° to 350°F

ASTM D2000

Classification System for Rubber Products

SAE AS568

Aerospace Size Standard for O-Rings

ISO 3601

Fluid power systems - O-rings

MIL-STD

Various military specifications

Need Fluorosilicone O-Rings?

We offer high-quality Fluorosilicone O-Rings for critical applications in aerospace, automotive, and chemical processes.